The construction industry is permanently facing new directives and regulations including new challenges. From this point of view, advanced technologies and modern building regulations increase the possibilities in timber construction. The flexibility and versatility of wood design allows a structural and aesthetic variety of building types and a great selection of applications. As a result wood is increasingly used in new construction projects these days. More and more architects, engineers and private developers realize the added value of wood structures as a cost-efficient alternative to steel and concrete. In summary wooden constructions are not only innovative and adaptable, but also efficient.

Fast Assembly

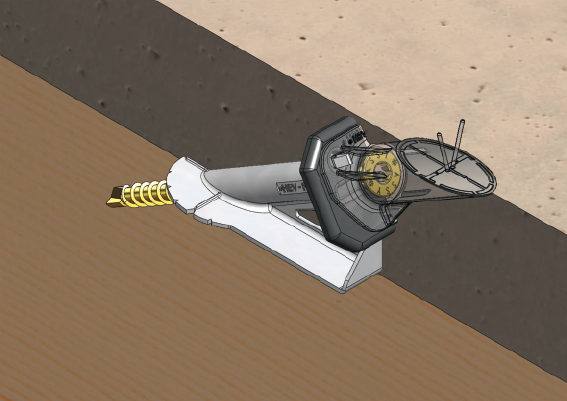

Great advantages of wood construction are the high speed and precision in assembly of the buildings due to the so-called "dry construction" on-site. So the buildings can be used right after the construction. Increasingly the hybrid architecture is also coming in the timber construction. This means that different materials will be connected together to form a load-bearing component in advance. For example, wood and concrete are often "married" in the ceiling area. This improves the load capacity, the span, the sound insulation and the fire protection of the building. To prevent or prolong the assembly process by introducing concrete and supporting the wooden beam ceiling during the concreting process SWG Production has developed an innovative system for this purpose. The precast-connector is used for the production of wood-concrete composite ceilings and allows a dry connection of wood and concrete. Thus, the "concrete structure" can be easily integrated into the assembly process of the wooden building. Due to the dry construction, the buildings can be loaded immediately and can be moved into or rented out faster than constructions on the worksite.

The whole process of prefabrication and fast assembly makes sure that the logistics on site are kept to a minimum. This leads automatically to a CO2 saving.

Carbon Sequestration

Over the whole lifetime of the building the wood saves carbon. Wood is considered the only material that stores more CO2 than it repels. Based on an annual growth per hectare, the carbon content of beech is the highest number at 12,478 kg CO2. The second most is the spruce with 11,441 kg CO2. The two advantages of the carbon bond and the shortened assembly time make a good combination. The dry systems also make the removing of the building easy at the end of its functional life, because the wood components can be reused.

CO2 Emissions and Fossil Fuels

Wood is not only a renewable resource that grows naturally. Wood also helps humanity to improve its environmental footprint. As early as 1976, the National Research Council carried out research that found that building with wood uses less CO2 and fossil fuels than conventional building with materials such as steel, concrete or aluminum. The use of wood from sustainable forestry even reduces CO2 emissions by 31%. It is shown from the study "Carbon, Fossil Fuel, and Biodiversity Mitigation with Wood and Forests".

The use of wood as a building material also reduces the global consumption of fossil fuels. By using wood from sustainable forestry, up to 19% of lignite, hard coal, peat, natural gas and oil can be saved. This can also be deduced from the study "Carbon, Fossil Fuel, and Biodiversity Mitigation with Wood and Forests".

However, most carbon dioxide and fossil fuels can be saved if fossil fuels are not used to manufacture, transport and construction of a building.

Fire Protection

The new construction also causes skepticism among the government at first sight. Finally, all safety aspects and guidelines must be fulfilled. Above all, fire protection plays a big role, too. Because of this, special fire protection tests were carried out before the construction of wooden buildings. The results of the test were amazing and confirmed the stability of wooden structures. The wood has even performed better in the test than other materials. In the test, the CLT panels were exposed to a fire of 1,600 degrees Celsius for one hour. Another example of the strength and reliability of the wood is shown in the video below. Solid wood carbonizes more than it burns and is therefore very fireproof.

Total Weight and Costs

Buildings made of renewable raw materials have a much lower total weight than conventionally constructed buildings. When using many components from renewable resources, the total weight can be reduced up to 25%.

From a cost point of view, building with wood is also worthwhile. Wooden buildings are no more expensive than comparable buildings in solid construction. The CO2 balance was much better for the timber construction method. Some of the wooden buildings even reached a negative carbon footprint during production.

Design and Modernity

The design of a building with wood is important, too. The modernity and beauty of wooden buildings are unmistakable. Due to the novelty of the concept daily original and innovative ideas and implementation possibilities arise. This background makes it even more attractive for many people to build with wood. After all, they can lead the way as a pioneer. Every new experience represents an advance in the timber construction sector, thus contributing to the appreciation of wooden buildings. Building with wood becomes more and more important.

Forest Clearing

More than 300 years ago the principle of "sustainable use" was already discussed. At that time a lot of wood was needed for mining in Germany. Hans Carl von Carlowitz has already recognized the problem and asked for ensuring the long-term use of the forests. In the long run a careful handling of resources as well as a continuous planting of new trees should guarantee a sustainable wood mining.

With this system of sustainable forestry and the correct handling the ecosystem survives, while enough trees can be used for building construction at the same time. The secret of sustainable forest management is that new forest areas are regularly created and old areas are replanted. So it's not that complicated.

One of the pioneers in the timber construction are the Scandinavian countries. They have developed a clever forestry system, too. In there, everyone is encouraged to plant three to four new trees for every cut down tree. "Today we have twice as much forest as we did have one hundred years ago," says Arne Olsson. The 1,000 m³ of wood that have been installed in every beach parking house, "produces the Swedish forest in just a minute."

Globally, there is enough extra wood to sustainably harvest and to construct buildings and bridges out of it. Both things are needed to reduce annual CO2 emissions up to 31% and fossil fuel consumption up to 19%. In total, 17 million m³ of wood can be harvested annually and re-cultivated with sustainable forestry without damaging the forest. Currently only 20% of that available wood (17 million m³) is used.

Conclusions

Building with wood has many advantages and should be expanded in Germany, too. Not only the short construction times, but also the rapid value creation and the cost-effective construction make it more and more interesting for developers and builders to think about wooden constructions. Also in the public area it becomes more famous. Not only in order to think about the next generation, it is important to already run a sustainable management of the forest today. Nevertheless, the consequence is that the effective use of wood makes an important but not overwhelming contribution to saving CO2. In the long term, the greatest savings potential will be achieved with sustainable forestry. This means that no more wood may be removed from the forests than can regrow. The goal of the strategy is to increase carbon storage in the forest while achieving an annual yield of wood. However, the cycle for the economic use of the wood is only possible if a corresponding demand exists. A desired goal must be to maintain and expand the demand for building materials from renewable raw materials.

Pioneer and Supplier for Timber Construction

SWG Production based in Waldenburg has stood for innovative and high-quality screws for major customers for decades. We set a good example and want to convince others that building with wood is a great and sustainable thing. The new building, planned by the company's own engineering firm SWG Engineering, will be such a wooden construction. Our engineers spent many months working on the structural design of the production hall. The symbiosis of new materials and new screwed connection variants leads to a unique project with a showroom, in which the use of our products in theory and practice can be seen. In the new production hall not only a lot of wood will be installed, but also many of our self-made screws and solutions will be used, too. This will directly demonstrate the use of fasteners from SWG Production.

However, we as SWG Production do not just want to be a pioneer in the field of timber construction. This type of building is also intended to inspire the public to think about building with wood, in order to create a good foundation for future generations. We are happy to support the construction projects of other property developers with our know-how, our services and our solutions of connection. Due to various approvals and certificates for Europe (ETA), America (ICC) and Canada (CCMC), our fasteners can be used in the most diverse regions and application areas. We offer our customers their own, individual solution and are happy to assist with our know-how, which we have established above all in the technical and planning area of the engineering office SWG Engineering. You are planning your own wooden building and need professional support? Then talk to us, we are interested in your projects and are looking forward to help.